Wood-Mizer Sawmills and Woodworking Equipment Help Advance Swedish Wood Industry

Sweden is a country with rich traditions of woodworking and reverence for forests which cover two-thirds of the country. With forests properly maintained, the wood-processing industry has a leading position in the Swedish economy. Many foresters, sawmillers, and woodworkers rely on Wood-Mizer equipment that helps their owners to run successful woodworking businesses throughout Sweden.

Crafted Wooden Eggs from Jämtland

In Persåsen, everybody knows the Wikners who manage a tourist resort and run a woodworking company offering a variety of wooden products. These days the company is supervised by brothers David and Mattias, but it was their father Leif who started it in the 1970s after being inspired by the beauty of the forests surrounding his home village. Their company Wikners i Persåsen offers everything made of wood – from original tables, chairs, and beds, to lamps, toys, cups, and photo frames, however, the company’s symbol and flagship product is a cockerel with wooden eggs.

“I love crafting wooden eggs because they symbolize the beginning of life. My specialty product is a range of artistic creations of eggs. They come in various sizes, colors, patterns, designs, and textures. I find hundreds of ideas on how to express my artistic visions – I make them using different kinds of wood and I present them in various configurations, such as half-opened eggs with a seed inside symbolizing a rebirth of nature. They aren’t just random products, since all these variations have their names and are presented in a catalog,” explains Leif.

David inherited the passion for wood from his father Leif and continues to fulfill himself by working this way in their family company. Even though Wikners i Persåsen employs only 10 workers, they manage their company smartly and flexibly. David has invested in various woodworking equipment to be able to meet his customers’ various requests. “In our company, we use all sorts of tools - standard hand tools, electric and machine tools, as well as more advanced cutting equipment like laser machines. There’s also the prototype Wood-Mizer CNC 5003 moulding machine on which we can quickly make a series of complex shapes and patterns. It’s particularly useful when we want to repeat precisely a sophisticated product, without engaging our workers' labor,” says David.

Sawmilling Line in Torsåker

Lars and David Viren from Torsåker work together in a small family company Woodab. Lars has been working with wood for more than 25 years and his son David opened his workshop just a few years ago to be able to complete his father’s range of products. Lars has upgraded his sawmill from the Wood-Mizer LT40 to the LT70 only recently. He claims it was a good decision because the LT70 sawmill is stronger, faster, and allows for high-volume production. David is glad he can expand the company’s production by adding the Wood-Mizer HR115 horizontal resaw and the MP360 planer/moulder. They make a perfect example of a family company in which a father passes on his knowledge and experience to his son. “I enjoy working with my dad outside, close to nature,” says David.

They split up the work between themselves so that Lars could focus on sawing logs on the LT70 sawmill, while David processes the material on his HR115 resaw. In the final stage of production David uses his MP360 planer/moulder to produce all the shapes and profiles requested by their customers. “With this division of work, we can speed up the production process and each of us can concentrate exactly on his part of the job,” notices David.

“We usually offer to our clients the typical construction timber, however, we keep getting more and more requests for special orders. I’ve observed that customers want to renovate their old houses retaining their original style. With my 4-sided MP360 planer/moulder I can recreate any shape for my customers, even though it’s sometimes quite a challenge. Every project brings something new for me to learn, and this is what I like most about working with wood,” points out David.

From a Portable Sawmill Owner to Successful Wood-Mizer Dealership

For Kjell Larsson, the Swedish dealer of Wood-Mizer in Storvik, Gästrikland, wood is a natural and nice material to work with. Swedish forests are hardwoods in the south and softwoods in the north. Many of them are harvested plantations of trees, so the wood is sourced sustainably and responsibly. The Swedes have been using wood as a construction material for generations. Kjell was no exception in that – he used wood for building his house and garage, as well as many other useful objects inside. “It wouldn’t have been able without a Wood-Mizer sawmill,” shares Kjell.

“I started to work for Wood-Mizer in 1992 and I remember well how innovative the first portable sawmill was on the Swedish market. Before that time sawmilling was based mainly on heavy and stationary circular sawmills which were ineffective and consumed a lot of energy. It was quite a challenge for us to convince the traditional sawmillers to upgrade to the bandsaw blades with thin-kerf technology. After all, it was worth it, as nowadays Swedish customers continue to rely on Wood-Mizer products and services. I have always worked towards building strong business relations with my customers. My clients appreciate the good service I offer – the availability of spare parts, resharpening services, technical advice, and more. At Wood-Mizer Sweden they can find a complete range of products for almost every sawmilling or woodworking project,” points out Kjell.

“People in Sweden realize they have been blessed with rich and beautiful forest resources, and they know how to use them smartly and responsibly. For me, the clean forests, mountains, and lakes are a true gift from nature. With the “Right to Roam” we can use forests by walking around freely and picking up berries or mushrooms. There is one condition though - we need to leave the forest in the same way as we found it,” explains Kjell.

Engineering Innovation for Woodworking Equipment from Östersund

Bo Mårtensson has been working with wood his entire life. He got interested in woodworking ever since he stepped into his uncle’s workshop as a young boy while continuing his education in mechanical engineering in the following years. “In the early 1990s, I developed a series of compact and highly functional planer/moulders which allow carpenters to produce their finished products from wood, quickly and effortlessly. My machines are used in small and medium-size workshops for making various panels, boards, furniture, frames, and more. In addition, this woodworking equipment is affordable and very easy to operate – back in the days it was a true innovation in the woodworking industry,” reminds Bo.

“I’m glad the woodworking machines from Sweden are now developed, produced, and sold under the logo of a renowned company like Wood-Mizer. Since it is a worldwide manufacturing company, they have advanced technology for production, many channels of distribution, excellent technical support for customers. Together we can offer a complete range of wood-processing machines. With merged knowledge and experience we can make a positive difference for woodworkers of all sizes,” explains Bo.

Like most Swedish people, Bo is conscious of the potential of forests and natural lands in his country. People treat forests with respect and admiration while using them as a valuable material for building nearly everything - from family houses and furniture to small everyday objects. “Wood-Mizer woodworking machines are a perfect solution for small carpentry,” says Bo, sitting in his flower house which he made himself using the Wood-Mizer MP260 planer/moulder and MP180 multi-planer, as well as the aspen wood sourced locally. “It seems that now Wood-Mizer’s motto From Forest to Final Form is becoming real, as the offering includes the entire range of machines for making a ready product - from sawmilling a log to finishing it on a planer/moulder.”

Wood-Mizer Sweden CNC AB

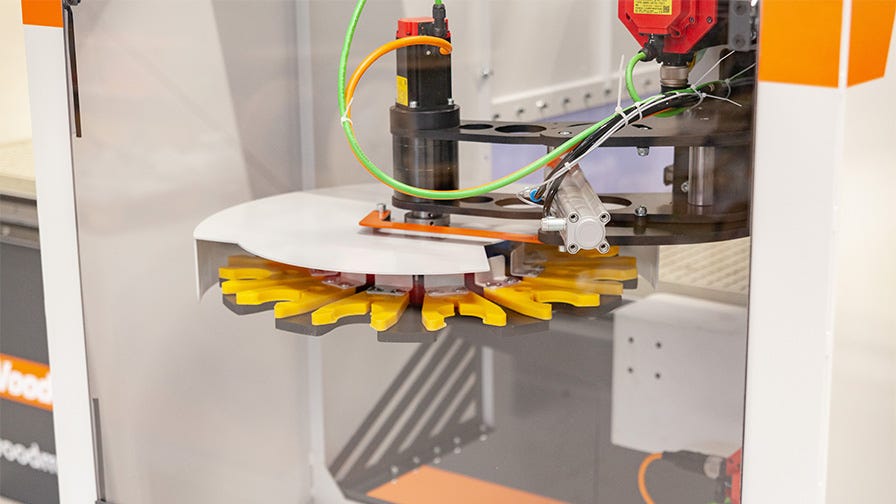

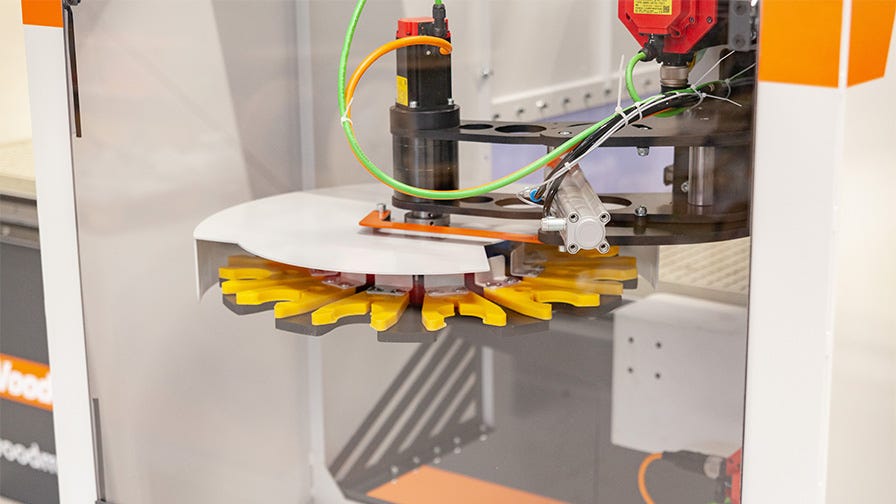

In response to growing demand from the market for new solutions in wood processing, Wood-Mizer is currently working on an advanced line of CNC machines (Computer Numerical Controlled). The Swedish division of the Research and Development office of Wood-Mizer has already designed the CNC 5003 machine capable of quick and smart profiling of flat materials. “It’s a 3-axis vertical spindle moulder with a vacuum nesting table for precise and repeatable moulding operations on flat wooden pieces,” explains Magnus Fransson, Wood-Mizer Project and Product Manager of the CNC machines. “We’ve delivered this prototype machine in various configurations to several companies in Sweden. The group of customers who would use the CNC might be either smaller arts and crafts workshops making very precise patterns on wood, or medium-size or larger production companies supplying sophisticated construction components for houses and buildings.”

Magnus has been working as an engineer since 2006. He enjoys designing and building machines that help entrepreneurs run successful businesses. He’s proud of the newest CNC 5003 machine – “We equipped it with a 12-position revolver for cutting tools and a Fanuc controller for advanced operation of the head and the spindle. The machine can mould flat pieces with maximum dimensions 300 x 150 cm which might be not only soft or hardwood, but also plastic, foam, aluminum, titanium or various composites,” points out Magnus. “The CNC 5003 and other upcoming machines from this line will complete perfectly the range of Wood-Mizer equipment by adding more high-tech to the finishing process of wood products.”

***