Functionality Above All – An In-Depth Review of the Most Valuable Features of Wood-Mizer Woodworking Machines

In this material, we will present the most important features of Wood-Mizer moulders/planers and ask the experts about their opinions on the woodworking machines. Let's see if the reviews from the Wood-Mizer specialists – Radoslaw Adamkiewicz, who deals daily with the engineering development of moulders/planers, and Adrian Bugala, who helps customers with technical issues, can confirm the opinions about the functionality, high precision, and efficiency of these machines.

What's the main application of woodworking machines? Are these machines indeed such a breakthrough and innovative idea of working with wood?

Woodworking Products include a wide range of machines for the final conversion of wood. They were designed in the 90s in Sweden, and today they are manufactured and developed in Wood-Mizer facilities in Poland and the USA. All woodworking machines can be divided into industrial and consumer products, and both groups can be further equipped with numerous accessory items and extension kits.

The basic engineering idea of the designers was to build one machine for a few woodworking operations so that the user could efficiently acquire the desired shape and dimensions of the material, and most significantly – with the best finish of the material surface. "Woodworking machines aim to improve the process of material shaping. Particularly they increase the work speed, quality, and precision, ensure the consistency of manufactured wood products, enable the mass production, and ultimately - raise the productivity," says Product Manager of Woodworking Products, Radoslaw Adamkiewicz.

With their simple construction and compact dimensions, moulders/planers match individual customer needs and small-to-medium-sized wood production enterprises. Many customers appreciate these machines because of their straightforward design and affordability. "If you decide to expand your business or add another manufacturing operation, you don't need to invest much money and find much workshop floor for these moulders/planers," explains Adrian Bugala, the experienced Technical Support Engineer of Woodworking Products.

What kind of construction projects can you make with the woodworking machines? Are operating moulders/planers easy and safe?

With the wide range of woodworking machines, you can select a specific unit for any wood construction or project that uses wood as a building material. "Depending on the type of moulder/planer, we can make finished products in various shapes and profiles – beams, boards, panels, furniture finish, doors, shelves, windows, frames, handles, toys, etc. Anything you want, as long as it's wood!" suggests Radoslaw Adamkiewicz.

A woodworking machine is relatively easy to use and maintain. Therefore, a person without much experience can still handle its operation after reading the user manual. Additionally, customers can watch video tutorials recorded for each model or make a phone call to get technical advice. The machines are designed as user-friendly, taking into account ergonomics but at the same time retaining their functionality. "Our moulders/planers have been designed with much care and attention for strict safety regulations required in the European market for this kind of machinery. Customers are assured this way that our machines will deliver the highest level of safety at work," says Radoslaw.

What sort of benefits does the customer get while purchasing a moulder/planer from Wood-Mizer?

Professional customer service and building good relations with customers have always been placed high on the priority list of Wood-Mizer activities. The company has gained respect and recognition among the wood industry customers not only by providing them with premium machinery but also by offering professional customer support. Customers can always count on assistance in making the right choices for the machinery they need for their business. We guide them through purchasing and shipping, and they can rely on the best technical service during the warranty and post-warranty period. The moment you become the owner of a moulder/planer, you acquire a premium machine with a long list of benefits.

Comparing the moulders/planers from Wood-Mizer with the machines of competitive brands, it's clear to understand that Wood-Mizer has been borrowing from its 40 years of rich experience in producing sawmills and bandsaw blades. The Woodworking Machines are a legacy of the Swedish MOReTENs, which had invented them and successfully sold them on the Scandinavian market for a few decades. Thus, the vast specialized knowledge, high manufacturing standards, and the wide network of Wood-Mizer distributors make an attractive offer for customers and bear tremendous potential for further growth of woodworking products.

"Wood-Mizer moulders/planers have a simple construction and are easy to use. They can be equipped with a range of accessories, cutterheads, tools designed for the specific woodworking models enhancing their functionality," says Radoslaw Adamkiewicz. "All woodworking machines are adjusted and set up in the factory, and with a few minor parts that need reassembling, they are ready to work right after unpacking. We put the machines through strict quality tests at every stage of production and assembly. Our moulders/planers are mechanically secured for shipment in the best possible way."

"The customers have at their disposal extensive technical advice and service support, and the spare parts or accessories are easily available at our warehouses," confirms Adrian Bugala.

A review of the most important functional features of Woodworking machines

Designing a woodworking machine that would be highly functional, compact-sized, premium quality, and price-affordable made the engineers set a few fundamental negotiables. First of all, such a machine must have a few cutterheads driven by separate motors, while replacing the knives should be quick and easy. Secondly, the work table, the infeed, and outfeed tables need to provide stability, precision, and durability that add to the quality of final products. Another essential feature of a good moulder/planer is its comfortable and safe operation and quick adjustment, allowing the user to work efficiently for longer periods. Finally, a perfect woodworking machine has a compact size while maintaining the stability of the construction, shielding the mechanical and electrical modules, and providing an effective sawdust exhaust mechanism.

=> The cutterheads, drive motors, and easily replaceable profile knives

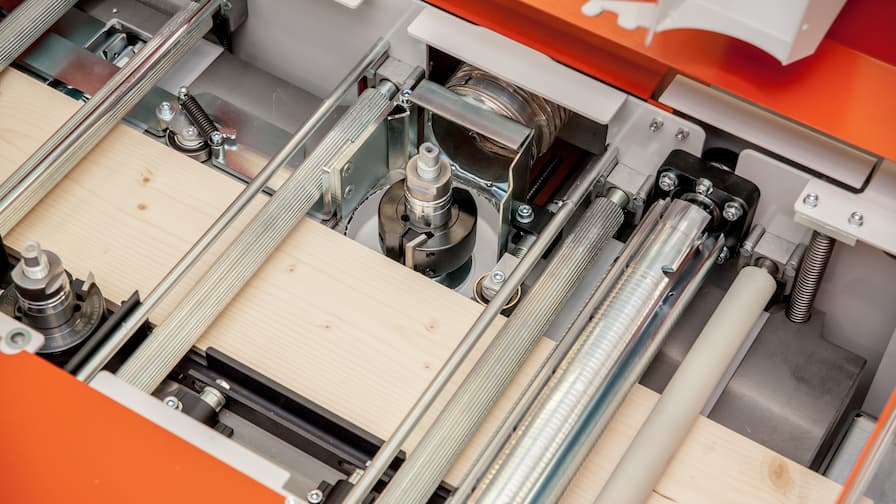

Wood-Mizer moulders/planers are designed for operation with a few cutterheads (top, bottom, right, left) to create a desired profile of the material after just one pass through the machine. "Just one pass through the MP260/MP360/MP365 is enough to profile the material simultaneously on four sides, giving it the desired shape and dimensions," assures Adrian Bugala.

"A separate motor powers each cutterhead, and the drive is passed using a belted gearbox. The cutterheads can be engaged on demand, which practically means reduced power consumption and lower levels of noise," explains further Adrian.

Replacing the knives on the cutterheads shouldn't take longer than 10 minutes, and the operation itself is intuitive and straightforward. It's the special grooves on the horizontal shaft that make exchanging the knives work so simple.

=>The solid steel infeed/outfeed tables and the robust cast-iron work table

Woodworking machinery needs stability and precision, and Wood-Mizer moulders/planers meet this challenge without much problem because they have solid infeed/outfeed tables made of galvanized steel. "Infeed table allows for easy feeding of big-size material through the machine. The same refers to the outfeed table, which feeds the material out of the machine stably and securely," confirms Adrian.

There's one notable feature of all Woodworking machines made by Wood-Mizer – it's a cast-iron table, placed very near the cutterheads and the feed rollers. The raw material used for the production of these tables is supplied by proven and trusted European foundries, and the process of maturing takes at least 12 months before it gets to the CNC planing station. The detailed manufacturing process of making the cast-iron table guarantees a high quality of this part. The cast-iron tables used in Woodworking machines are remarkable for their enhanced resistance to wear and deformation, high level of vibration damping, and the increased stability even with all electrical motors working with full power.

=> Quick adjustments and an easy-to-access control panel

The Woodworking machines' high level of functionality develops several simplistic and effective ways of adjustment and maintenance. "All regulations and adjustments of the woodworking parameters are done quickly and precisely by a hand crank or a lever when planing on the MP160/MP180. The main work table moves vertically on four trapezoidal screws providing much stability and the accuracy of adjustments," explains Adrian. "The control panel is clear and logical. The operator can position it ergonomically so that it could always be within easy reach. It includes the main power switch, a light indicating the presence of voltage, an emergency stop, the switches engaging the electrical motors separately".

=> The compact and lightweight construction of Woodworking machines

The compact size makes the Woodworking machines very comfortable moving around a small workshop. The optional caster wheels help to roll it aside and clear the room for other necessary operations. "At each cutterhead, there's a sawdust exhaust port to direct the sawdust precisely into the exhaust outlet," notices Adrian. "The steel and robust machine case provides safety for the operator at work and the protection for the parts and components, such as electrical motors, gearboxes, drive chains, etc."

The best offer of woodworking machines on the market? Yes, confirmed!

The Wood-Mizer specialists leave no doubts describing Woodworking machines. These tools are fantastic in changing wood into final products! The knowledge and experience of Wood-Mizer specialists Radosław Adamkiewicz and Adrian Bugała are the best assurance that at the moment you purchase a moulder/planer from Wood-Mizer, your expectations and requirements are going to be fulfilled, and in most cases, even surpassed.